Birla’s GreenTrack™, Powered by Blockchain Technology, Traces ‘Forest to Fashion’

28 April, 2023For a long time, the only information provided to consumers about a garment’s provenance was a “Made-In” label with minimal details. This might have been sufficient in the past, but consumers today won’t accept this level of opacity. They want to know exactly where and how the merchandise they buy was manufactured, starting with raw materials.

“Sustainability in textiles is a growing trend in the fashion industry as consumers are more conscious and aware of the environmental impact,” said Vaishali Kamble, assistant general manager, business development at Birla Cellulose. “Consumers are shifting their behavior to buy and use clothing that is sustainable and kind to the environment.”

Birla Cellulose’s business focuses on sustainably sourced and produced man-made cellulosic fiber products certified by the FSC (Forest Stewardship Council) and SFI (Sustainable Forestry Initiative). Considering this, the company’s value chain partners have been requesting an auditable proof of record to show that the viscose apparels produced are indeed manufactured from Birla Cellulose FSC fiber.

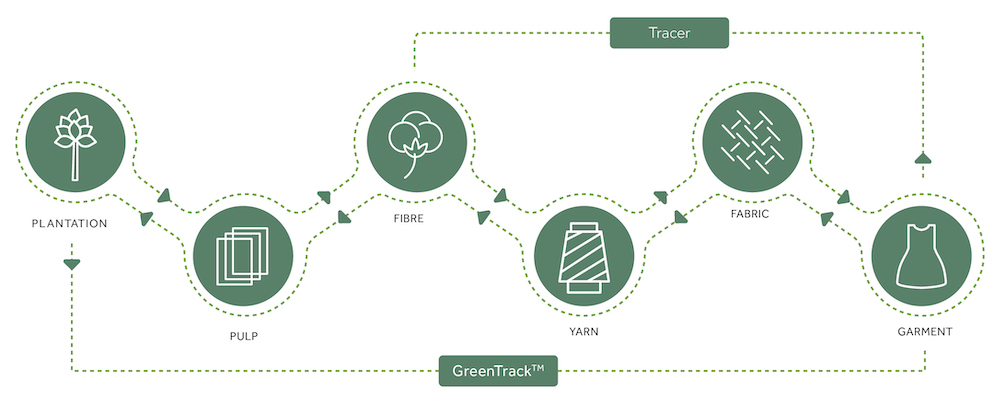

To meet this demand, Birla Cellulose designed the in-house traceability tracking platform GreenTrack™. This platform captures complete traceability across the complex value chain—starting with the origin of the pulp source and through to the final garment—and shares this information in a transparent manner through blockchain technology.

“The textile industry is considered to be self-reliant because products at each stage are used as the raw material for the next stage of production,” said Kamble. “But the process of tracing each step of the clothes manufacturing process—from sourcing of the raw materials to the factories where those materials are made into garments—was missing.”

GreenTrack™ starts at the ingredient level. In partnership with its pulp supplier, Birla Cellulose shares information about the specific sustainably managed forest from which wood was sourced. For wood-based materials, it is critical to be able to prove that inputs did not come from ancient or endangered forests that have been identified by conservation and environmental organizations.

Birla has developed a proprietary DNA tracker that is embedded into fiber at the production stage. The tracer remains intact on the fiber across the supply chain, enabling it to be traced in the value chain at any subsequent stages of the production process—including yarn, fabric and garment manufacturing. For verification of the tracer, brands, garment makers and mills can send a sample—either a full garment or two meters of fabric—to Birla’s labs in India and China for testing.

“Current chain-of-custody processes fall short in physical or material authentications, which may lead to false claims and the sourcing of fibers and materials with unchecked environmental risks,” said Tiana Quinny, manager of fiber traceability at Birla Cellulose. “GreenTrack™ allows real-time access to the raw material journey at every stage of the production process across the complex textile value chain. The technology was built to have two-fold provenance tracking: value chain traceability and source verification through a molecular tracer. The traceability feature improves accountability for the value chain, thus encouraging the brands to adopt the technology.”

Brands can then share this information with consumers at retail. “GreenTrack™ provides a platform for traceability and transparency that helps to strengthen the brands’ and consumers’ connections,” said Quinny. “The consumer can scan the code and get the complete visibility from forest to fashion, which helps them choose the proper product and expand adoption of the Aditya Birla Group’s cellulosic fibers.”

A number of Birla sustainable fibers are traceable via GreenTrack™, such Livaeco viscose, Livaeco modal, circular Liva Reviva and high-strength Birla Excel.

In addition to sustainability, GreenTrack™ provides brands complete visibility and real-time tracking of their orders and shipments.

Since it was introduced in 2019, GreenTrack™ has grown to include 90-plus active brands and around 1,400 value chain partners who are registered and using the platform in India, China, Turkey and Bangladesh. For supply chain partners and brands, GreenTrack™ is available without any additional cost.

GreenTrack™ provides valuable authentication across the entire product life cycle. “A critical step today is verifying that the materials used are sourced sustainably, processed responsibly and can provide the information needed to ensure their value can be recaptured at the end of use,” said Kamble.

Click here to learn more about Birla Cellulose.

Source: https://sourcingjournal.com/sustainability/sustainability-materials/birla-cellulose-greentrack-blockchain-traceability-platform-429152/