Birla Cellulose’s Commitment to Water Stewardship leads to Innovations in Viscose Technologies

Water is Life

Water is essential for human existence and required by all forms of life on Earth. This valuable resource is becoming increasingly scarce because of climate change and increased exploitation of existing reserve. A UN report predicts that by 2025, nearly 3.4 billion people worldwide will be living in ‘water-scarce’ countries.

Water scarcity poses major risks to the global economy. Agriculture depends on the availability of water, and over 80% of water is consumed in agricultural activities. Industrial processes consume around 10% of the total surface water. Considering higher level of agricultural and industrial activities is needed to support the growing population, it is critical to focus on efficient management of water sources.

Closing the Loop on Water in Viscose Manufacturing

Man Made Cellulosic Fibres (MMCF) such as viscose, modal, and lyocell are nature-based fibre derived from sustainably sourced wood. Conventional viscose fibre manufacturing process requires a large quantity of water, and access to water both in terms of quality and quantity is of paramount importance.

For Birla Cellulose, one of the global leaders in the MMCF industry, this means creating viscose fibre through a process that can reduce its water consumption radically. This is especially true for sites such as Grasim Industries, Nagda, situated in water-stressed regions.

Birla Cellulose is committed to reduce its water intensity by 50% by 2025 from its baseline, and improve the availability of water, aligning its initiative to the call of action by SDG 6 and SDG 12 for improving the management of water resources efficiently and consuming natural resources responsibly.

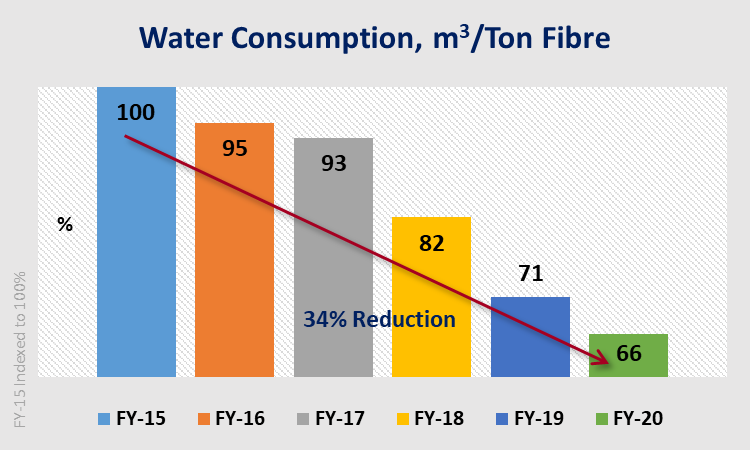

This commitment is demonstrated by a steady decrease in water consumption at the global sites of Birla Cellulose as depicted in the below graph. Innovations in low water usage viscose technology have not only reduced the water consumption but also wastewater pollutants significantly.

Fig 1 – Water consumption trend chart

Philosophy of 4R (Reduce, Reuse, Recycle and Regenerate)

Birla Cellulose applied the 4R Principles (reduce, reuse, recycle and regenerate) in its operations for closing the loop on water, resulting in several technological breakthroughs which have reduced the water consumption significantly.

Birla Cellulose’s Indian sites – Nagda, Vilayat and Kharach – spearheaded innovation in closed-loop technologies for water, and these were widely adopted by all its viscose fibre manufacturing sites.

- Reduce water consumption by better technologies that require less water. Low water technologies were developed and deployed in core viscose processes such as fibre washing, chemicals recovery, cooling towers, and fibre washing.

- Reuse water in the process or other applications multiple times. Circular technologies have enabled water to be used several times in finishing and recovery processes.

- Recycle water with innovations in wastewater recycling technologies and advanced membrane-based technologies. The water quality achieved after recovery is better than raw water quality from the river.

- Regenerate water through harvesting (by building dams and reservoirs) to store water in the rainy season that can be used later in the year.

Going Beyond Water Positive – Water Stewardship at Nagda, India

Grasim Industries Limited started operations at Nagda in 1954 when the remote village was uninhabited barren land. The opportunities created by Grasim have now transformed Nagda into a thriving town with a population of nearly 3 lakhs and have helped improve its socio-economic status. The capacity of the site has since expanded from 15 tonnes per day (TPD) to 395 TPD.

However, this rapid growth of community, agricultural, and economic activities has led to increased water requirement than supply from nearby surface water bodies, especially during the summer. For Grasim, this meant ideating new ways to manage water resources and applying path-breaking multiple strategies beyond water positivity.

Over the past several decades, Grasim has funded massive infrastructural projects in Nagda for building dams and reservoirs. The water harvested is over three times the water Grasim annually needs for its own use.

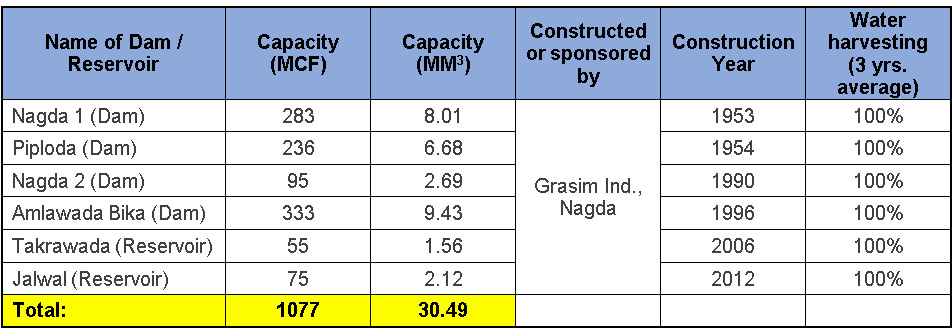

Table 1: Dams and Reservoirs constructed by Grasim Nagda, for storing water in rainy season

Water from these dams and reservoirs serves the needs of about 200,000 people in over 50 villages for hygiene and agricultural purposes. The availability of water throughout the year has been one of the main reasons for socio-economic growth in the region and highly appreciated by the community and the local government.

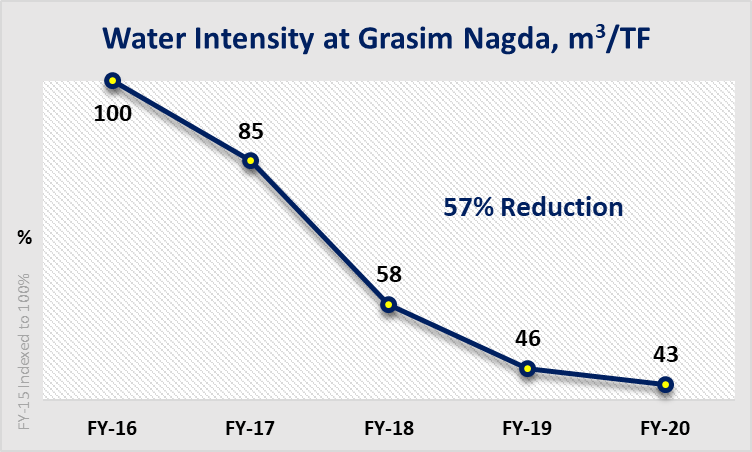

The Birla Cellulose site at Nagda has reduced its water intensity by nearly 60% in the last five years by following the 4R principle as depicted in the below graph. Nagda is currently the global benchmark for being the lowest in specific water consumption in the viscose industry.

Fig 2 – Water intensity trend chart of Grasim Nagda

Innovation through Zero Liquid Discharge (ZLD)

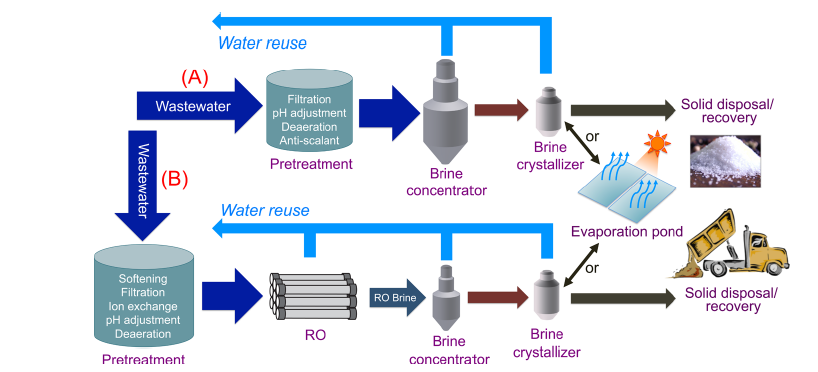

Some situations demand unique solutions. Looking at the diminishing availability of water in the Chambal River basin, Nagda is implementing a new solution to prepare for the future. Zero Liquid Discharge (ZLD) has never been developed in the viscose industry because it needs to be modified to be effective.

Fig 3 - Graphic for Reference only: The Global Rise of Zero Liquid Discharge for Wastewater Management: Drivers, Technologies, and Future Directions – American Chemical Society

Grasim’s ZLD strategy aims to recover the maximum possible amount of salts to be recycled and used in other manufacturing processes, creating minimal solid waste. ZLD will recover almost 95% of the total wastewater feed. The system will be operational in 2021, making Nagda the first viscose fibre site globally to achieve ZLD in manufacturing. It will also be the first viscose plant in the world with zero wastewater generation.

Way Forward

Protecting and conserving natural resources through innovative water management practises is a priority for Birla Cellulose. The goal is to reduce water intensity by 50% by 2025 from the baseline year 2015. As of 2020, 35% of this reduction has been achieved, and more projects are in progress for further reduction. The water initiatives are aligned to Birla Cellulose’s vision to be the leader of sustainable business practices in MMCF industry.

Related stories

- Grasim’s CSR Video

- Grasim Industries has won the prestigious “CII IP Award 2023 in Best Trademark Portfolio”, in the category of Large Manufacturing/ Engineering Companies

- GRASIM, SFD- Nagda received the 7th CSR HEALTH IMPACT AWARDS in the category of “Water Harvesting Project–Silver”

- Miyawaki Forest – Making Mother Earth Greener

- Grasim bagged the reputed 5th edition “The CSR Journal Excellence Awards 2022” (1st Runner-up) in the category of Agriculture and Rural Development